Contact us with any inquiries.

GST added to sales within Canada.

We Ship Worldwide.

Vintage British cables produces the highest quality restorations of classic smiths instruments . The only instruments I will use on my restorations are those restored by Vintage British cables, I won't put a substandard component on the bikes I build. Andy's services are thorough, thoughtful and participatory. Andy asks questions and engages you to verify he is providing you with precisely what you need. The cables provided by Vintage British cables are seconded to none. The all-important dimension of protrusion is spot on and the overall cable is simply the best in its construction. The pricing of the cables and instrument restorations is excellent. I use Vintage British cables services and products with confidence.

Anthony Nicholson,

Union Jack Cycle LTD

RE 8 instruments: It is rare that I pay

anyone to do something for me! I am hard to please and am usually

disappointed. I’ve been telling myself all day waiting to pick up the box

to just be happy with what I get from you and move on. Well, I am elated

with what you did! They are beautifully restored! Thank you, and feel

free to quote me! G.M.

The instruments

arrived today. They are PERFECT, absolutely beautiful! Thanks so much.D.V.

The speedometer and cable arrived today. I installed both

immediately and am elated to report that the kit works perfectly -- and the

clock looks as new, too! C.R.

Items arrived safe and sound and all I can say is "Wow"! B.R.

Superlative craftsmanship!

Very pleased with the look and finish. Thank you very much for a job well done.

W.E.

The

package arrived safe and sound. It looks beautiful! Now I'm going

to have to paint the bike. :} Thank

you very much!! M.T.

I received the package on Wednesday. You’ve done a superb job on

the restoration. It is absolutely stunning. G.H.

I received the gauges today. Best XXX bucks i've

spent in a long time. They look great., thanks again. D.G.

Received both instruments

today...... they look excellent. G.T.

I received this morning the tacho…Everything in this deal was absolutely

perfect !!! And the tacho is incredibly beautiful !!! P.F.

Beautiful : Thanks for the great job and

wonderful service. P.B.

The tachometer has

arrived. It is beautiful. J.M.

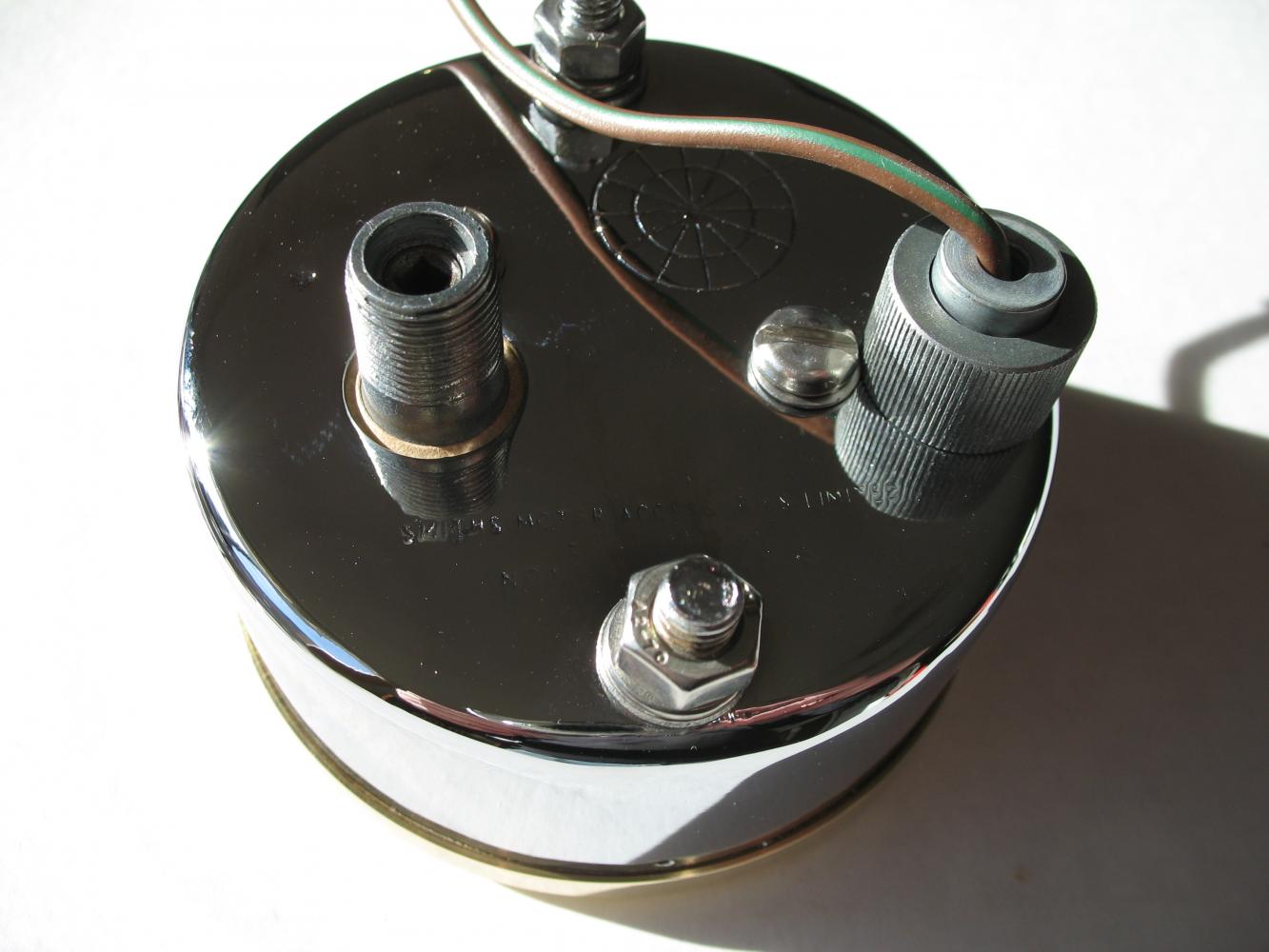

SMITHS Chronometric Speedometer, General Description

The Chronometric Instrument, which is of the mechanical type and is driven by a flexible shaft, indicates the speed at which the vehicle is travelling,

by the number of revolutions the driven shaft makes during fixed time periods. Between these periods, the pointer of the instrument remains

Stationary and ensures accurate speed reading. The instrument is really two in one, a speed instrument and a distance recorder:

1. The speed indicator movement operates as follows: The camshaft gear (which is driven through a train of gears by the main spindle) drives the

camshaft the camshaft through a friction clutch. Attached to the camshaft is the wheel of the lever escapement (similar in principle to that usually

employed in clocks and watches) which ensures that at all speeds at which the the instrument is designed to operate the rotational speed of the

camshaft is constant, being controlled by the escapement that provides the time basis on which the mechanism operates in period cycles of 0.8 seconds.

The mechanism is in motion at a speed within its operational range. The uppermost cam on the camshaft actuates a rocking arm which causes

periodic engagement of the commander pinion with the integrator wheel. Since the time of the engagement is constant at all speeds, but the rotational

speed of the commander pinion is proportional to that of the driving flex, the integrator wheel will be rotated by an amount depending on the driving

flex speed. The movement of the integrator wheel is communicated, by driving pegs or pins, to the corrector wheel, thence to the stabilisator to

which is fitted a hollow shaft that carries the pointer. Return springs are fitted to the integrator and the corrector wheels, the teeth of which are

engaged by spring fingers which are lifted in turn by the camshaft. The stabilisator is free on its shaft and is coupled with the integrator in such a

manner as to give a pointer reading which is the average of several cycles of the mechanism.

The complete sequence is therefore:

a) Rocking spindle is engaged with integrator wheel, which is rotated according to the speed to be measured, carrying with it the integrator,

stabilisator and pointer drive.

b) Rocking spindle disengages.

c) Integrator wheel returns to zero position, leaving integrator, stabilisator and pointer in position.

d) Rocking spindle re-engages integrator wheel and the spring finger of the recorder is momentarily lifted to allow the recorder to take up

It will be seen that the recorder wheel, stabilisator and pointer remain fixed between the intervals of engagement of the rocking spindle, with the

result that the pointer takes up a position, at the end of each interval, corresponding to the number of revolutions the driven shaft has made during

that period.

2. The Distance recorder Mechanism consists of two ratchet wheels and two sets of counters, trip and total, mounted on a shaft and fitted into the zinc

On careful examination it will be seen that one face of each counter has been formed with ratchet teeth and the other has a well defined cam profile. All

counters are identical with the exception of the trip decimal counter which is red.

The counter drum ratchet teeth are locked in comb springs. At every complete turn of a counter drum, a section of the comb spring is depressed by

the counter drum cam, allowing the next counter to turn one unit before being again locked.

The distance recording counters are turned by a pawl operated ratchet, mounted on an eccentric fitted to the worm wheel spindle, the worm wheel being

driven by the main shaft.

It must be emphasised that maintenance and repairs must be carried out by qualified persons using genuine Smiths parts.